Raybow Brevard is your Global|Green|EHS Focused|R&D Centric CDMO.

Raybow Brevard is the U.S. headquarters for Raybow USA, Inc., a division of Raybow. We want to be an integral component of your Research and Development Team.

You can be confident that Raybow will resolve your synthesis problems and stay in step with your evolving R&D/Clinical objectives.

A Brief History of Raybow Brevard

Raybow acquired PharmAgra Labs, Inc. in November 2019. The newly acquired company is now Raybow USA, Inc. and is the headquarters for Raybow's operations in North America. To learn more about the acquisition please view our news release.

The Raybow Brevard site has a 20 year history of providing contract R&D in organic and medicinal chemistry.

The company also has a facility for cGMP production of Active Pharmaceutical Ingredients for use in Clinical Trials and low-volume production. The company continues to be managed by it's co-founders who are experienced scientists. The facility was designed specifically for the unique requirements of synthetic organic chemistry research and there is room to expand the site.

PharmAgra Labs was founded in 1999 by Peter Newsome, Ph.D. (formerly Senior Research Chemist, Rhone-Poulenc) and Roger Frisbee (formerly Vice President, Pisgah Labs, Inc.). The company was initially located in a leased facility in Arden, NC (near Asheville in western North Carolina). In 2002, the need for more space and design flexibility led to the purchase and renovation of the current 11,400-square-foot facility located in Brevard, NC.

Construction of a cGMP laboratory for the preparation of APIs was completed in 2007 and the company began development of its first product immediately thereafter. The company successfully completed our first FDA pre-approval inspection (PAI) in July of 2009 with no 483s issued.

Services - Raybow Brevard

Raybow's Brevard site delivers the high-quality custom synthesis and contract research services necessary to accelerate your internal research and development programs.

Raybow's Brevard site has the skill and experience necessary to meet a wide range of outsourcing needs. We can assist clients with all phases of the discovery-development-clinical process. At its core, Raybow is a chemistry company wholly focused on the preparation of mg to kg quantities of target molecules for our clients. We also have the manufacturing resources of our other International sites along with hundreds of scientists at our overseas R&D centers available to us should the need arise.

Raybow delivers the high-quality custom synthesis and contract research services necessary to accelerate your internal research and development programs.

We provide medicinal chemistry support services for the synthesis of target compounds, reference compounds, starting materials, intermediates, specialized reagents, and other compounds of interest. We can also develop divergent synthetic routes for rapid analog preparations in support of SARs studies.

Our chemists work in a well-equipped facility with ready access to literature/reaction databases and literature retrieval services.

Some examples of our services include:

- Medicinal chemistry support services

- Synthetic route design and optimization

- Resynthesis

- Preparation of starting materials, intermediates, and final targets

- Preparation of reference compounds and metabolites

- Small-volume (mg-kg) manufacturing

- Combinatorial building blocks

- Chiral synthesis/enantiomeric resolution

- Stable isotope derivatives

Raybow has developed efficient manufacturing processes from a number of laboratory-scale syntheses (obtained from literature, client and/or Raybow research). Our management has experience with cGMP manufacturing in equipment up to 2,000 gallons. This knowledge and experience enables us to develop efficient, real-world solutions to our clients’ production needs.

Recent projects include a successful multiyear collaboration with a small biotech company requiring the development of a commercial API manufacturing process starting from a 12-step medicinal chemistry route. We designed a new manufacturing process that we used to produce multi-kilogram lots of product. This process was later transferred to a large scale cGMP manufacturer. Production of key intermediates was transferred to both domestic and offshore suppliers.

Other projects include the development of commercial multi-kilo processes for several generic drugs that have been transferred to large-scale manufacturers. We have also developed an efficient kilo-scale photochemical manufacturing process for a pharmaceutical intermediate.

Process chemistry services include:

- Process development

- Route scouting and selection

- Optimization

- Scale-up

- Process documentation

- Tech transfer services, domestic/offshore

When your API is ready to transition to the clinic, Raybow can rapidly and economically meet your requirements for API Clinical Trial Material. We synthesize milligram to multi-kilogram lots for clinical studies and low volume commercial production in our cGMP synthesis laboratory. A wide range of chemical processes can be accommodated in glass reactors up to 72 liters. Larger quantities can be accommodated by transfer to large scale cGMP manufacturers.

We are an FDA inspected facility. We successfully completed our first FDA pre-approval inspection (PAI) in July of 2009 with no 483’s issued.

Our cGMP services include:

- Synthesis of milligram to multi-kilogram lots for clinical studies and commercial production

- Process validation

- IND / NDA / ANDA support documentation

- Impurity isolation, characterization and synthesis

- Analytical methods development and validation

- Impurities identification and synthesis

- Reference standard preparation, characterization and documentation

- API stability studies according to ICH guidelines

- Product release testing

Raybow provides in-house production of mg to kg quantities of both cGMP and non-cGMP materials. If your production requirements exceed our in-house capabilities, we have good working relationships with domestic and offshore large-scale manufacturers. We can also provide technology transfer services to clients who want to work directly with their manufacturers.

Production services include:

- Production using client-provided or Raybow-developed processes

- In-house production, mg to kg scale for cGMP and non-cGMP products

- Manufacture of up to MT quantities using domestic or offshore collaborators

- Technology transfer to client-specified domestic or offshore manufacturers

- Process validation

PharmAgra Labs routinely solves complex analytical problems as part of our custom synthesis program. We have therefore developed significant expertise in analytical chemistry services, which we offer as a stand-alone service to our clients. These services include:

- Analysis and interpretation using HPLC-DAD/CAD/ELSD, GC (MSD/FID), LC/MS, 400 MHz NMR (1H, 13C, 19F, 31P), FT-IR, etc.

- Analytical methods development and validation

- cGMP analysis

- Product release testing

- Identification of unknown compounds

- Separation and identification of complex mixtures (optical isomers, geometric isomers, etc.)

- Chemical conversion/derivatization in support of difficult analytical determinations

Raybow makes available a broad range of useful chemical intermediates. Get started by requesting a custom synthesis quote on our quote request form.

All of the compounds available have either been made by Raybow in the past or are available from a Raybow partner company.

Our scientists offer the extensive expertise in Organic Synthesis and Analytical Chemistry required for successful litigation. We understand that speed, effective communication, reliability and confidentiality are critical to successful outcomes.

- Patent Procedure Replication: Careful replication/documentation of patent procedures with extensive analytical support. We have significant experience supporting activities related to the Hatch-Waxman Act.

- Life sciences: Support legal challenges facing pharmaceutical, medical device and other companies involved in the life science industry.

- Patent infringement litigation support: Support IP challenges by designing experiments to evaluate chemical synthesis/manufacturing processes.

- Case evaluations and data review: Assist with scientific evaluation of claims, including the review of opposing data, interpretation of technical results and conclusions.

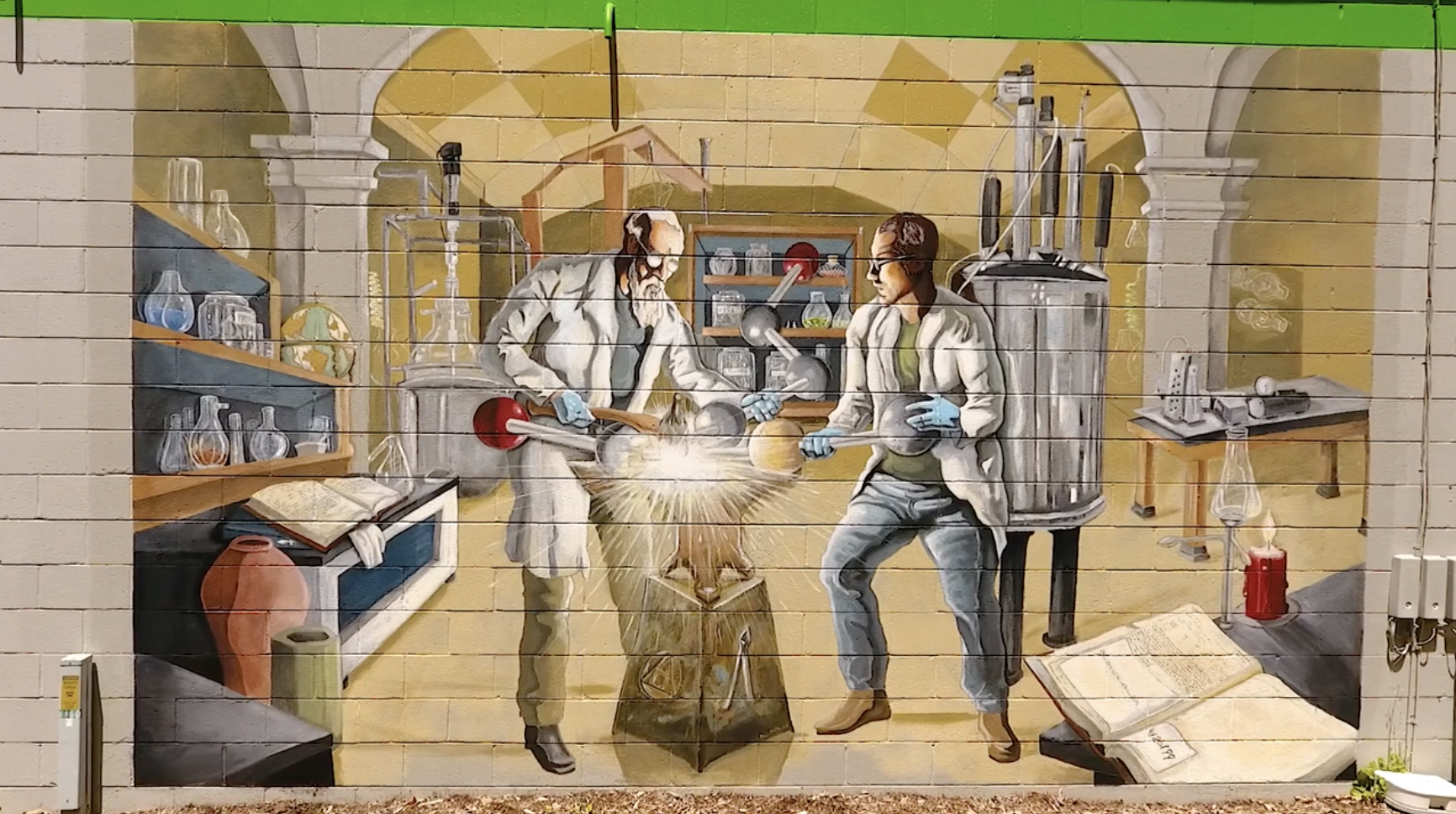

Raybow Brevard Gallery

Our Facility

Raybow's Brevard site is an 11,400-square-foot facility in Brevard, NC. The site includes a state-of-the-art laboratory specifically designed for the unique requirements of synthetic organic chemistry.

Our site is easily accessible to clients via the Asheville, NC and Greenville/Spartanburg, SC regional airports as well as the Charlotte International airport.

Some highlights of our facility:

- Company-owned site on 3.5 acres

- 11,400-square-foot building

- Class 100,000 cGMP suite

- Safe, compliant, exceeds codes

- Fully sprinkled

Site security includes:

- Security system

- Fire alarm system

- Fenced and gated with restricted access

The center of activity at Raybow Brevard is the research laboratory, a 3,000-square-foot lab containing 19 fume hoods divided into three work areas. The easily accessible analytical lab and flammable solvent storage room help create a spatially optimized work environment with all distances minimized.

The laboratory is separated from the office area by a storefront glass wall that not only allows for diffusion of natural light into the lab area, but also serves to increase visibility for safety purposes. To facilitate communication, chemists’ desks are located in the office area across from their group leader.

The research lab features:

- 3,000 square feet

- 17 bench hoods

- 2 walk-in hoods with removable benches

The kilo lab is designed for safe execution of larger-scale reactions. The room is separated from the rest of the building by 2-hour firewalls and, like the rest of the facility, is protected by a sprinkler system. The lab is equipped with a 180-square-foot reactor booth (dedicated dry chemical fire-suppression system) and two walk-in hoods. The reactor booth allows for large portable equipment (reactors, work-up stations, centrifuge, etc.) to be rolled in as needed.

Features of the kilo lab include:

- 700 square feet

- (2) 8’x4’ Walk-in Hoods with Secondary Containment and Dry Chemical System

- 10′ x 18′ reactor booth featuring:

- Dedicated dry chemical fire suppression

- 7500 CFM ventilation

- Reactors and work-up stations to 72L

- (4) 20L Rotary evaporators

- Parr hydrogenator to 2.5L

- Parr pressure reactor 19L/2,000 psi

- Ozone generator

- (2) Kugelrohr distillation apparatus

- Fractional distillation equipment

- 12L spinning band still (30 theoretical plates)

- Prep MPLC systems (up to 24L silica at 600 mL/min)

- Wiped-Film Evaporator (0.06m2, 0.04-5 Kg/hr)

- Centrifuge (14″, 7L, 2500G)

- Sprinkler system

- Isolation by 2-hour firewalls and doors

In 2007, we constructed a cGMP laboratory for the preparation of clinical trial materials and commercial APIs. In July of 2009 we successfully completed our first FDA pre-approval inspection (PAI) with no 483s issued.

Some features of the lab include:

- All air HEPA filtered

- Class 100,000 laboratory and access/egress rooms

- Class 10,000 packaging room

- All rooms differential pressure controlled

- 4 Synthesis areas

- Door magnetic interlocks on all access/egress rooms

- ~1000 sq ft

- 4 Bench Hoods, 1 Walk-in

- 2 gowning rooms

- Raw materials staging/glassware washing room

- Dedicated, segregated GMP warehouse area

An easily accessible but protected analytical lab is located adjacent to the research laboratory. This area, with its own dedicated HVAC system, is used for cGMP analyses (validated instruments) as well as more sensitive instrumentation (NMR, LC/MS, etc.).

Some features of the analytical lab include:

- 850 square feet

- Agilent OpenLAB CDS data system

- NMR, 400 MHz (1H, 13C, 19F, 31P)

- LC/MS/MS (APCi, ESI)

- GCs (MSD, FID)

- Headspace GC

- LCs (UV, DAD, CAD, ELSD, MS)

- Prep-LC

- FT-IR

- UV-Vis

- Karl Fischer titrators

- pH meter

The flammable liquids bulk storage area is located a short distance from the rear of the research laboratory. This provides our chemists with ready, safe access to bulk solvents and to temporary hazardous waste storage.

Features of the flammable liquids room include:

- 300 square feet

- Continuous ventilation

- 2-hour fire separation

- Dry chemical fire suppression

- Secondary spill containment

- Earth grounding/bonding for containers

Raybow Brevard

Acres

Square Feet

Secured

Additional Site Information

The Brevard area is serviced by the Asheville Regional Airport (AVL). Greater flexibility in flight schedules is generally available from the airport in Greenville/Spartanburg, SC (GSP), a one-hour drive away or the Charlotte airport (CLT), a two-hour drive.

The Holiday Inn Express and the Hampton Inn are located within a five-minute drive from Raybow Brevard. For convenience to the Asheville airport, the Clarion Inn-Asheville Airport is about 25 minutes away.

Directions

From the East or West on I-40:

- Go to Asheville on I-40.

- Take I-26 East toward Hendersonville.

- Take Exit 40 (old exit 9) — the NC 280/airport exit.

- Turn right at the end of the exit ramp, toward the Asheville airport (NC 280 West).

- Go 16.0 miles on 280. (After about 13 miles you will come to a major intersection of NC highways 64 and 276, but continue straight. The Holiday Inn Express will be on your left shortly after passing through this intersection.)

- Just after passing Ingles supermarket on the left, turn right onto McLean Road (there is a 5/3rd Bank on the corner).

- Go just 0.15 miles and turn right into the driveway (the address is 158 McLean Road). Raybow is a gray and green building sitting far back from the road. There is a sign on the building.

From the Asheville, NC Airport (AVL):

- When you exit the airport, turn right on NC 280 West.

- Go 16.0 miles on 280. (After about 13 miles you will come to a major intersection of NC highways 64 and 276, but continue straight. The Holiday Inn Express will be on your left shortly after passing through this intersection.)

- Just after passing Ingles supermarket on the left, turn right onto McLean Road (there is a 5/3rd Bank on the corner).

- Go just 0.15 miles and turn right into the driveway (the address is 158 McLean Road). Raybow is a gray and green building sitting far back from the road. There is a sign on the building.

From the Greenville, SC Airport (GSP):

- Take I-85 North toward Charlotte. Take I-26 West toward Asheville.

- Take Exit 40 (old exit 9) – the NC 280/airport exit.

- Turn left at the end of the exit ramp, toward the Asheville airport (NC 280 West).

- Go 16.0 miles on 280. (After about 13 miles you will come to a major intersection of NC highways 64 and 276, but continue straight. The Holiday Inn Express will be on your left shortly after passing through this intersection.)

- After passing Ingles supermarket on the left, turn right onto McLean Road (there is a 5/3rd Bank on the corner).

- Go just 0.15 miles and turn right into the driveway (the address is 158 McLean Road). Raybow is a gray and green building sitting far back from the road. There is a sign on the building.

Raybow USA, Inc. is a custom synthesis company that conducts contract research and development in organic and medicinal chemistry.

For current openings including opportunities at all our global sites visit our Job Postings Page.

Thank you for your interest in Raybow USA, Inc. We are an equal opportunity employer.